component processing systems Stopper and cap processing

Welcome to castus The stopper processing specialist HANAG has joined our group

We are delighted to inform you that HANAG Steriltechnik AG has been integrated into castus.

As of March 31, 2021, castus (Germany/Ochsenhausen) became the new owner of HANAG Steriltechnik AG (Oberwil/Switzerland), with the transfer of the entire employees and HANAG customers.

Cleaned. Sterilised. Dried. Stopper handling with the Component Processing System (CPS) for pharmaceutical primary packaging

castus, one of the world's leading manufacturers of transfer systems, has joined forces with the stopper processing specialist HANAG, based in Oberwil. Henceforth, castus sterile systems GmbH & Co. KG will bundle the production of stopper handling systems within the castus group.

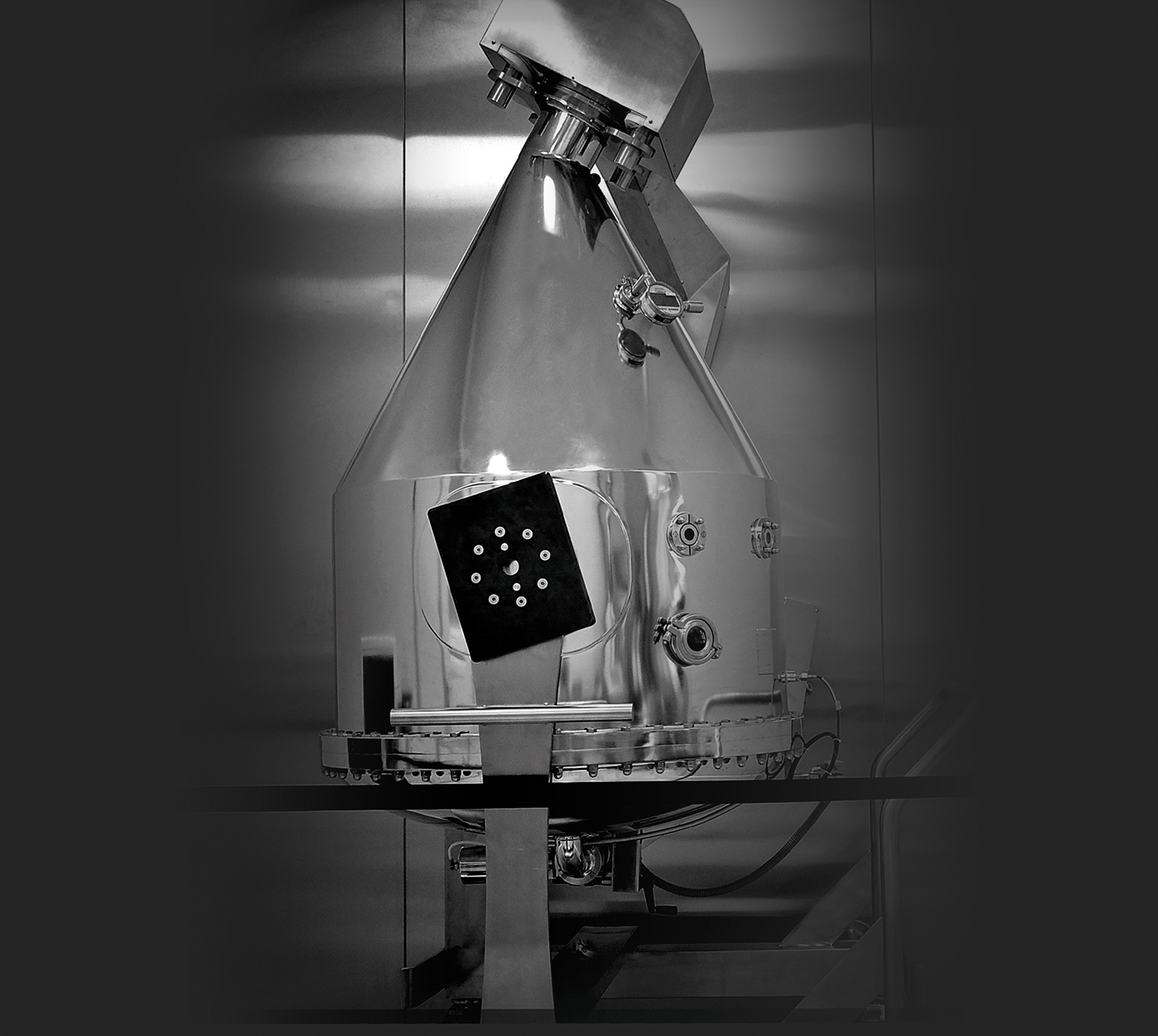

The Component Processing System (CPS) includes the following process steps: Washing, siliconising, sterilising, drying and cooling. The sterile and efficient manufacturing process is not interrupted. Seamlessly the system fits into the filling process for aseptic transfer.

Easy handling of the Component Processing System (CPS) Load, process and transfer of stoppers and caps

The system consists of four main components:

The container on its trolley, the loading station, the processing unit and the lifting mechanism. It constantly provides sterile stoppers, while handling is facilitated by simple docking at different stations.

Do you have individual questions on this product or need addtional details? Please contact us! Our consultants team is looking forward to your enquiry.

Technical data Special requests possible on request

Capacity: Variable process volume up to 350 litres

Operational scenario: Stopper and cap processing, filling lines for vials, carpules and syringes

Interface: Open system interface technology for unloading into any container

ADVANTAGES AT A GLANCE

Reduction of particles to a minimum

Smooth treatment

Homogeneous silicone distribution

High drying efficiency

High process reliability

Unloading options for any environment

More products

The alpha Port Flushfloor Reliable and individually tailored

Flush to floor transfer port

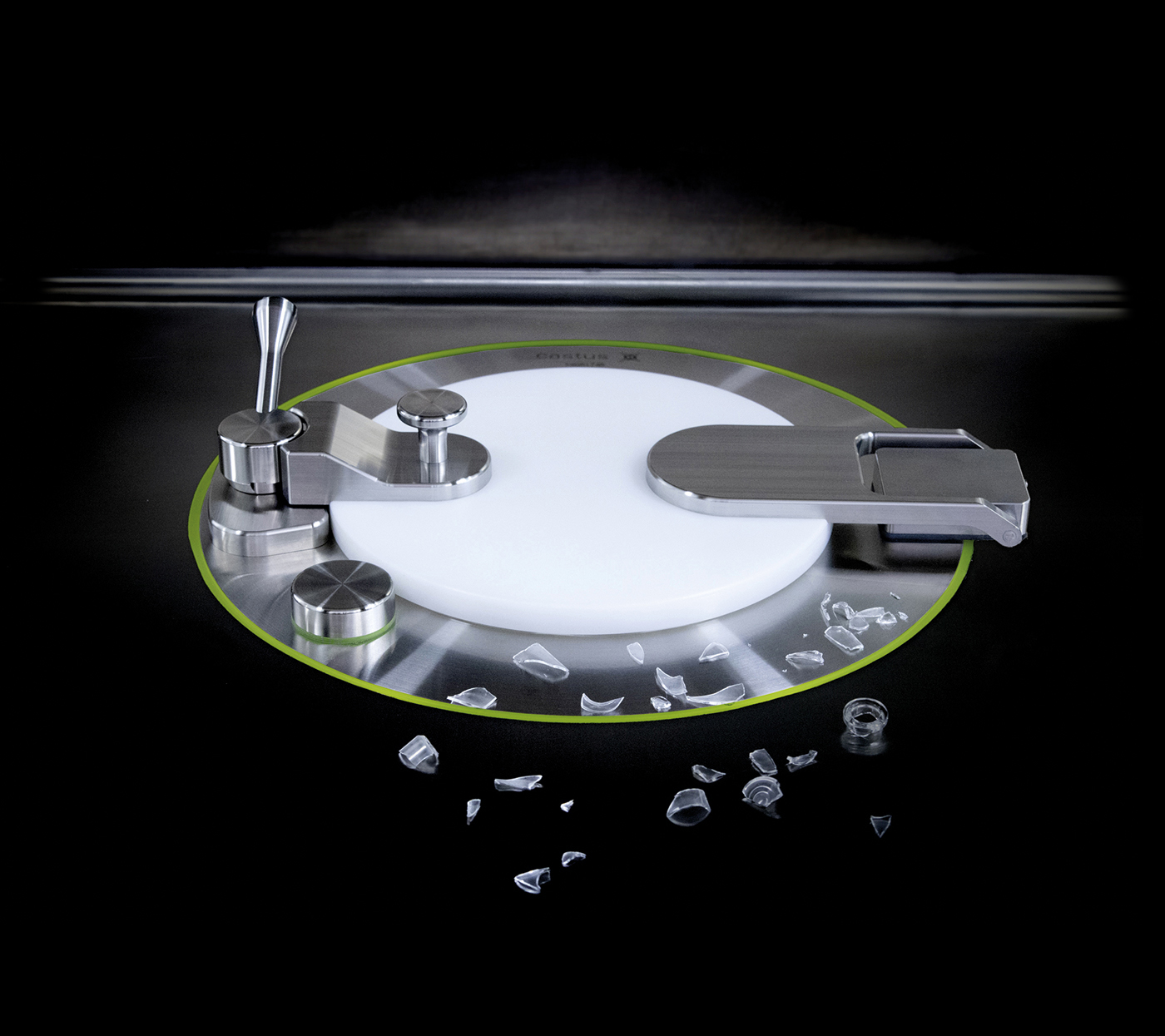

The castus beta Container 316L Simple, safe and contamination free

Perfect loading and unloading of components.

Cage Stopper handling for small batches

The alternative to single use products.